non destructive testing pipe wall thickness|ndt pipe thickness : manufacturer Non-destructive testing should be applied on insulated and uninsulated piping in areas where CUI and damage is likely to occur, as well as areas identified as suspect as a result of a Mechanical Integrity inspection. 服务. 新闻. 联系. 驱动技术. 欢迎访问亚特兰传动技术(上海)有限公司。. 作为从事高品质驱动系统开发、建设和生产的德国中型家族企业,Atlanta已在80多年时间内展现了驱动领域专业水准并为全球客户提供驱动解决方案。. 我们是驱动技术的制造商,在位于 .

{plog:ftitle_list}

21 de fev. de 2024 · 1 de junho de 2023. Vamos verificar se o site maxbuscas.tech é confiável e seguro para usuários da internet. Nossas ferramentas irão vasculhar a página para buscar várias informações relevantes sobre o domínio, que podem mostrar se a página é de confiança para navegação.

Ultrasonic thickness measurement (UTM) is a non-destructive testing method used to inspect .Non-destructive testing should be applied on insulated and uninsulated piping in areas where .Non-destructive testing should be applied on insulated and uninsulated piping in areas where CUI and damage is likely to occur, as well as areas identified as suspect as a result of a Mechanical Integrity inspection.

The wall thickness gauge enables the quick and simple detection of the first signs of wear and .

We developed a method to map the wall thickness of an plate or a pipe-wall using guided .Ultrasonic thickness gauging is a widely used nondestructive test technique for measuring .

Wall thickness measurement as part of Non-destructive Testing is one of the most common uses of ultrasonic technologies. In addition to the classic measurement of wall thickness as part of quality control, our precise wall .

Digital X-ray radiography is a well established method for non-destructive detection of .Ultrasonic Thickness Testing (UTT) can be used for testing a limited number of locations . 7.2.4 The ultrasonic thickness examination of each test specimen shall be performed in each grading unit. 7.2.5 Scan each grading unit to determine the area(s) of corrosion. 7.2.6 Determine the minimum remaining wall thickness measurement for each grading unit. 7.2.7 The minimum remaining wall thickness for each Grading Unit shall be recorded

Ultrasonic testing is a nondestructive discipline termed NDT – meaning that it does not damage, alter, change, degrade, influence, or impact the material under evaluation in any possible way. . Confirm wall thickness prior to welding; . The research and design of a pipeline corrosion defect detection technology based on electromagnetic ultrasonic non-destructive testing technology can accurately locate the location of corrosion defects in pipelines .A 2D probe yields added convenience and flexibility, but users can get the same resilience through NDT scanning equipment that can probe different welding types. Pipeline Scanning. Overall, NDT scanning has several advantages, such as: Wall thickness measurements; Sensitivity to surface flaws and subsurface flaws; Stellar flaw detection of .

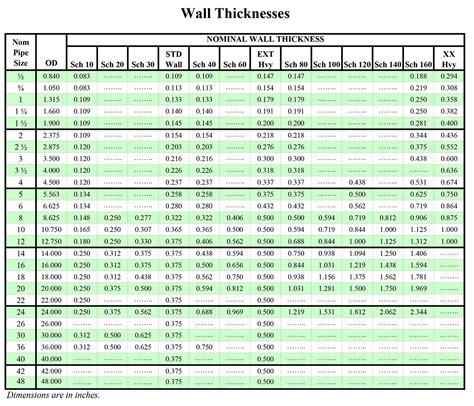

Cylinder Wall Thickness Calculator Internal Pressure (psi): Cylinder Radius (inches): Allowable Stress of Material (psi): Joint Efficiency (0.7 to 1): Calculate Wall Thickness Here’s a comprehensive table covering everything you need to know about Cylinder Wall Thickness, including factors affecting thickness, typical formulas used, materials, and .under-tolerance on new pipe wall thickness. As an example, a Schedule 40, 3-inch pipe nozzle has a nominal wall thickness of 0.216 inch, so the actual wall . Non-destructive testing should be applied on insulated and uninsulated piping in areas where CUI and damage is likely to2. Tomographic wall thickness mapping We developed a method to map the wall thickness of an plate or a pipe-wall using guided waves [1,2]. It uses the effect that the phase velocity of most ultrasonic guided wave modes depends on the thickness of the wave guide. In a plate symmetrical and anti-symmetrical modes exist.

Non-Destructive Testing (NDT) is the use of technology to examine an object or material’s structure, imperfections, . Remaining pipe wall thickness is what matters. NDT is a necessity for acquiring concrete evidence about the state of the piping and vessels in your system.GGS performs reliable non-destructive pipe testing so you can manage the operational health and safety of your industrial and commercial process piping. . Pipe Wall Thickness. Double wall measurement on insulated and uninsulated piping. Watch the Video. Pipe Wall Thickness Acceptance Levels (a resource)

NDT Testing Methods for Piping. Baker Testing Services provides many non-destructive and destructive tests and inspections for piping systems, welded pipe, and pipeline applications. Ultrasonic Thickness Testing (UTT) Accurate, digital ultrasonic measurements can instantly determine pipe wall thickness.In order to monitor the integrity of these critical assets to operations, non-destructive testing (NDT) is the best method as it involves little to no downtime. There are many methods of NDT but ultrasonic testing (UT) is the most effective solution for corrosion and erosion detection via wall thickness measurement.Our Non-Destructive Testing (NDT) engineers are highly qualified and experienced, having worked on most major projects in Hong Kong since 1966. . Storage Tank Shell & Water Pipe Wall Thickness; Radiographic Examination Radiographic Examination of Welded Joints and Components (X-ray & Gamma Ray Source) X-Ray Fluorescence (XRF) TestThe Profiler was inserted into one end of a pipe to look at one wall and then at a pipe location that contains a 0.034-in. groove. Next, a 0.022-in. shim was added to the 0.3-in. wall thickness. The Profiler was subsequently removed from the pipe and positioned around the pipe with the shim in place; measurement data were taken.

A staple of non-destructive testing, MISTRAS deploys ultrasonic testing (UT) to detect, locate, and size corrosion/erosion, flaws, cracking, and more. . the walls of piping, vessel, storage tank, and other assets. MISTRAS offers UTT spot inspections, and long-term, remote wall thickness monitoring for pipes and vessels in high-temperature and .Wall thickness range: UT tools are able to cover up to 60mm wall thickness. These tools can even offer the same good resolution (0.06mm) for the wall thickness measurement over the full range from thin to thick wall. New UT tools can measure down to 2 mm remaining wall thickness, for internalThe single most important application for ultrasonic gauging is measuring the remaining wall thickness of metal pipes, tanks, structural parts, and pressure vessels that are subject to internal corrosion that can't be seen from the outside.

Non-Destructive Testing . Defining Pipe Wall Thickness Acceptance Levels for Your In-Service Piping. Implementing a baseline for your organization that defines specific action at different severity levels of piping deterioration, and what those levels are, is a necessary inclusion for operating within the parameters of PSM and RMP . Set in the context of condition assessment of critical infrastructure, the integrity of arbitrary sections in the conduit is derived with a bespoke robot kinematic configuration that allows dense pipe wall thickness discrimination in circumferential and longitudinal direction via NDT sensing with guaranteed sensing lift-off (offset of the .Wall thickness measurement as part of Non-destructive Testing is one of the most common uses of ultrasonic technologies. In addition to the classic measurement of wall thickness as part of quality control, our precise wall thickness gauges can also be used to detect damage caused by erosion and corrosion on, for example, ships, storage tanks, pipelines, and cranes.

MISTRAS' pipe wall thickness trending solutions utilizes ultrasonic testing (UT) technology to detect, trend, and report wall thickness measurements for overhead lines, reducers, elbows, tees and more. Our monitoring sensors are attached to the pipe with a clamp, rather than through welding, ensuring that structural integrity is not affected .UTT is one of the more common NDT techniques due to ease-of-use. Ultrasonic thickness testing measures the wall thickness of a properly prepared sample (pipe) by touching the transducer to the surface of the pipe. This method is very good at measuring the thickness of a single-layer sample – optimally, a clean, flat, sample at moderate .

Applied Technical Services offers ultrasonic thickness testing (UTT) to determine material thickness and to measure the thickness of coatings and/or linings. Our technicians have been trained to calibrate the UTT gauges based on materials. Frequent NDT Pipe Inspection is aimed at assessing any changes to the pipe wall thickness, which involves testing for corrosion and erosion as well as examining the quality of welds in pipes. Over time, Corrosion from the outside, erosion from the inside in addition to pressure applied by gases or fluids flowing through a pipe may affect the .Ultrasonic Testing (UT) is a powerful non-destructive testing (NDT) method that relies on the mechanical vibration of sound waves in the ultrasonic range (frequencies greater than 20 kHz) to uncover volumetric discontinuities within solid materials. In UT, both compression and shear waves play a pivotal role in investigating the internal nature .In the field of industrial ultrasonic testing, ultrasonic thickness measurement (UTM) is a method of performing non-destructive measurement (gauging) of the local thickness of a solid element (typically made of metal, if using ultrasound testing for industrial purposes) based on the time taken by the ultrasound wave to return to the surface. This type of measurement is .

Ultrasonic and Wall Thickness Testing Ultrasonic testing is useful for the detection of surface discontinuities. To accomplish this, high frequency sound waves are beamed into material and reflections of the sound are analysed. This method can be used to locate internal discontinuities in most metals alloys for a wide range of applications including the testing .PosiTector UTG Ultrasonic Wall Thickness Gauges measure the remaining wall thickness of materials such as steel, plastic and more using ultrasonic technology. Ideal for measuring the effects of corrosion or erosion on tanks, pipes, or any structure where access is limited to one side. Select from corrosion, low frequency, precision, and multiple echo thru-paint models.

thickness of pipe wall

pipe wall thickness standards

pipe wall thickness chart

Resultado da 10 de abr. de 2017 · 1、女性的物化. 一切的开端. 一切的结尾. 在这个社会里, 男的,睡得越多,越骄傲. 女性,越容易被睡,越卑微. 看起来很平常的道德观. 越想越恶心. 逼良为娼. Justin刚开始只是为了炫耀自己钓到了汉娜. 结果照片传开了之后汉娜就变成了slut. Alex不想承认自己没睡到Jess. 让汉娜成了最 .

non destructive testing pipe wall thickness|ndt pipe thickness